We received new products - Visit our catalog!

Optimizing Driver Performance Against Lebanon’s Unpredictable Grid Fluctuations

The Daily Grind: Surviving the Lebanese Grid

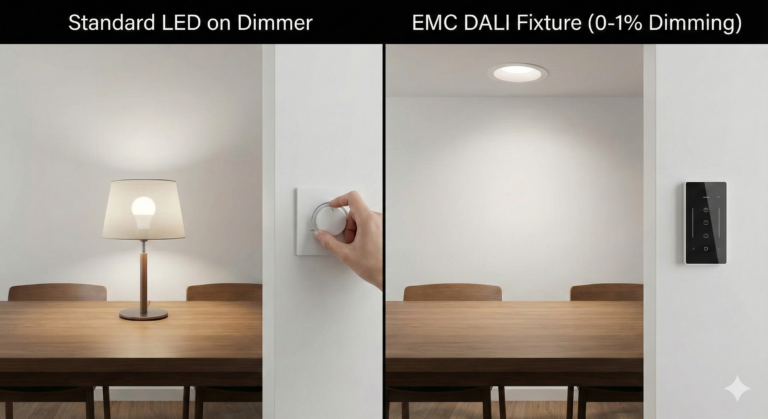

Ah, the symphony of generator switching! That familiar flicker as the neighborhood power transfer kicks in, or the sudden, unsettling surge to 260V (or sometimes a painful sag to 160V) from your local provider. For us engineers in Lebanon, this isn’t an anomaly; it’s the daily reality our LED drivers must endure. We all know the tell-tale smell of a burnt driver, the dead fixture, and the frustration of explaining yet another failure to a client who was promised “European quality.” Cheap imports, often with suspiciously optimistic specifications, simply don’t stand a chance against the relentless assault of our unpredictable grid. They’re designed for stable conditions, not for our unique, unforgiving electrical rollercoaster.

INPUT VOLTAGE RANGE: The specified range of AC input voltages over which an electronic device, such as an LED driver, is designed to operate reliably and meet its performance specifications. Exceeding or falling below this range, especially repeatedly or for extended periods, can lead to component stress, reduced operational lifespan, or immediate catastrophic failure.

The Engineering Reality: Why “Standard” Fails Here

The core issue lies in component specification and thermal design. Generic drivers, often boasting an impressive but misleading PF > 0.95 and a supposed 140lm/w efficiency, are built with cost optimization, not grid resilience, in mind. When a driver designed for a nominal 230V ± 10% encounters prolonged operation at 260V or below 180V, its internal power factor correction (PFC) circuitry and critical electrolytic capacitors are subjected to extreme stress. Higher voltage means higher peak currents and increased internal heat generation across components like MOSFETs and rectifiers, while lower voltage demands higher current draw to maintain output power, stressing the same components.

- Capacitor Degradation: Undersized input capacitors, rated marginally for voltage, quickly degrade under constant over-voltage spikes, leading to reduced capacitance, increased ripple, and ultimately, premature failure of the entire driver. Their internal temperature rises dramatically, effectively halving their expected lifespan for every 10°C increase.

- Thermal Management: Cheap imports often skimp on adequate heat sinks and thermal potting. Without robust thermal management, the internal junction temperatures of semiconductors skyrocket during fluctuations, leading to component breakdown far earlier than their advertised 50,000-hour lifespan. We’ve seen drivers rated for 85-265VAC fail within months because their internal components couldn’t handle sustained operation at the edges of that range under real-world Lebanese conditions.

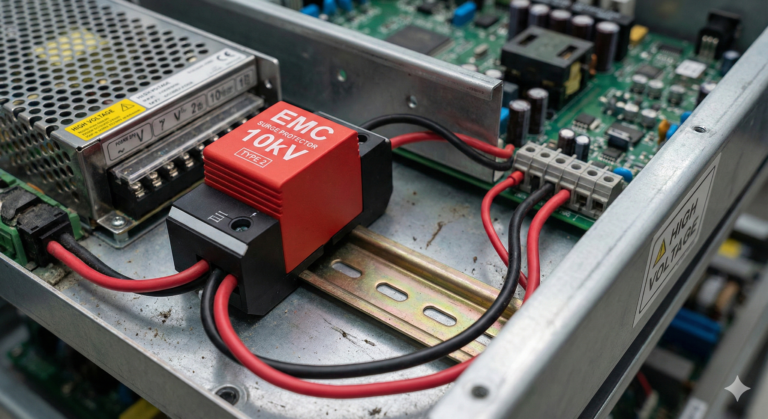

- Surge Protection: A proper driver for our market needs multi-stage surge protection, often rated for at least 4kV differential and 6kV common mode, rather than the bare minimum found in most standard units. This isn’t just about lightning; it’s about generator switch transients.

The EMC Superled Advantage: Engineered for Lebanon

This is where local engineering isn’t just a preference; it’s a necessity. At EMC Superled, our drivers are not just assembled; they are designed and tested right here in our factory in Lebanon. We understand the specific stresses of a 260V spike or a prolonged 170V sag because we live it too. Our R&D focuses on:

- Robust Component Selection: We specify industrial-grade capacitors with higher voltage ratings and extended temperature ranges, capable of handling the constant thermal cycling and voltage fluctuations unique to our grid.

- Enhanced Thermal Design: Every driver enclosure and internal layout is optimized for maximum heat dissipation, ensuring component longevity even under adverse conditions.

- Wider Operating Ranges: Our drivers are engineered to truly operate efficiently and reliably across a significantly wider input voltage range than typical imports, often with enhanced protection against sustained over/under voltage conditions.

When a driver from EMC Superled is installed, you’re not just getting a product; you’re getting local support. No need to wait 3 months for a replacement container to clear customs from a manufacturer thousands of miles away who doesn’t understand our unique challenges. We’re here, with spare parts, local warranty, and engineers who speak your language, both literally and technically.

Optimize Your Project, Don’t Just Replace

Don’t fall for the glossy brochure specs of drivers not designed for our reality. If you’re constantly replacing burnt-out drivers or struggling with inconsistent lighting performance, it’s time for a professional assessment. Bring your compromised or failed drivers to our lab at EMC Superled. Our engineers can analyze the failure mode, diagnose the root cause, and demonstrate how our locally engineered solutions offer superior resilience and a true return on investment.

Alternatively, for your next project, book a consultation with our team. Let’s discuss your specific needs and show you how EMC Superled drivers can guarantee uptime, efficiency, and consistent lighting performance, even when the grid decides to play its daily games.