لقد تلقينا منتجات جديدة - زوروا كتالوجنا!

The “Graveyard” in Your Basement: The Hidden Financial Cost of Disposable LEDs

By Anthony Gemayel, Electrical Engineer Estimated Reading Time: 5 Minutes

If you manage a large facility a university, a hospital, or a residential tower I bet you have a room I like to call “The Graveyard.”

It’s that dusty corner in the basement piled high with broken LED fixtures. They aren’t old; some are barely two years old. But they are dead. And because they are sealed, glued-together units imported from a catalog, you can’t fix them. You can’t find the spare driver. You can’t match the color temperature with a new batch.

So, they sit there. A pile of wasted capital.

At EMC Superled, we believe that in 2025, buying a “disposable” industrial light is financial suicide. Here is why the “cheaper” quote you got from an importer is actually costing you double.

The Definition: Total Cost of Ownership (TCO)

Total Cost of Ownership (TCO) in lighting isn’t just the price on the invoice. It is the calculation of: (Initial Cost) + (Energy Cost) + (Maintenance Labor) + (Replacement Cost of Failed Units).

Most procurement officers focus on the Initial Cost. But if a $50 light fails in 18 months and costs $100 in labor and downtime to replace, its TCO is actually $150.

1. The “3-Month Wait” Nightmare

Let’s say you manage a shopping mall. You bought 1,000 downlights from a supplier who imports “European Spec” lights (usually just re-branded generic imports).

Two years later, a section of your mall goes dark. You call the supplier.

- The Problem: “Oh, that factory updated the model. The new ones look slightly different.”

- The Delay: “We don’t stock the spare drivers. We have to order them. It will take 12 weeks via sea freight.”

Can you afford to have a dark hallway for 3 months? Can you afford to have mismatched lights that make your ceiling look like a chessboard?

The EMC Advantage: Because we manufacture in Lebanon, we don’t wait for shipping containers.

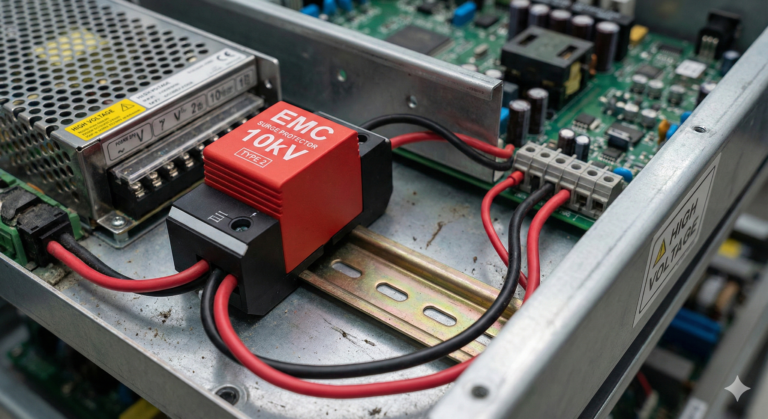

- Spare Parts: We stock thousands of drivers, chips, and housings right here.

- Speed: We don’t say “3 months.” We say “Tomorrow morning.”

2. The “Disposable” vs. “Repairable” Economy

Most imported LEDs are built like smartphones: glued shut and designed to be thrown away. If the driver (a $15 part) fails, you have to throw away the whole $100 fixture. This is insanity.

We build Modular Systems. If an EMC light stops working after 5 years, you don’t throw it in the graveyard. You unscrew the back, swap the driver, and put it back up.

- Cost of Repair: $15.

- Cost of Replacement: $100+.

Multiply that by 500 lights in a tower, and you are looking at tens of thousands of dollars in savings over the building’s life.

3. “Made in Lebanon” is a Financial Hedge

This isn’t just about patriotism; it’s about economics.

When you rely on 100% imported fixtures, you are exposed to:

- Global Shipping Costs: Prices jump whenever a shipping lane gets blocked.

- Customs Delays: Your project stalls because a container is stuck at the port.

- Currency Exposure: You are paying for logistics, insurance, and middlemen margins in fresh dollars.

By buying from a Lebanese manufacturer, you cut out the ocean freight, the customs delay, and the middleman. You are paying for the product, not the boat ride.

4. The ROI Math (A Simple Example)

Let’s look at a real-world scenario for a Warehouse Project (100 High Bays).

Option A: The “Cheap” Import

- Price: $80/unit.

- Total: $8,000.

- Failure Rate: 10% in Year 2 (common for cheap heat sinks).

- Replacement Cost: $800 (new lights) + $1,000 (scissor lift rental & labor).

- Total Cost Year 2: $9,800.

Option B: The EMC Industrial Spec

- Price: $110/unit.

- Total: $11,000.

- Failure Rate: <1% (Robust Engineering).

- Warranty: 5 Years (Real Local Warranty).

- Total Cost Year 2: $11,000.

By Year 3, Option A has overtaken Option B in cost. By Year 5, you have bought the cheap lights twice.

The Lesson: You can pay for quality once, or you can pay for garbage forever.

Conclusion: Stop Filling Your Graveyard

Next time you are reviewing a BOQ, ask the supplier three questions:

- “Where is your spare parts warehouse?”

- “Can I open the fixture and change the driver myself?”

- “If I need a replacement tomorrow, can you deliver it?”

If they hesitate, close the catalog and call us.

We invite all procurement officers to visit our factory. Come see the spare parts inventory yourself. We don’t hide our stock because we actually have it.