لقد تلقينا منتجات جديدة - زوروا كتالوجنا!

The Engineer’s Guide to Industrial LED Lighting: Why Your “50,000 Hour” Bulb Failed in 6 Months

By Anthony Gemayel, Electrical Engineer Estimated Reading Time: 6 Minutes

If I had a dollar for every time a factory manager in Lebanon told me their “European Specification” LED high bays burned out after one summer, I could probably retire.

It’s a common story: You buy a light that promises 50,000 hours of life. You install it in your warehouse in Choueifat or your factory in Bekaa. Six months later, it’s blinking like a disco, or it has turned a weird shade of blue.

Why does this happen? Did the manufacturer lie?

Well, yes and no. They gave you the specs for the LED chip inside a lab in Germany. They didn’t give you the specs for the fixture sitting in a 45°C corrugated steel roof in Lebanon.

At EMC Superled, we don’t just import boxes; we engineer energy management solutions. Today, I’m going to stop acting like a salesman and start talking like an engineer. Here is why your industrial LEDs are failing and how to read a datasheet without getting scammed.

What is Industrial LED Lighting? (The Definition)

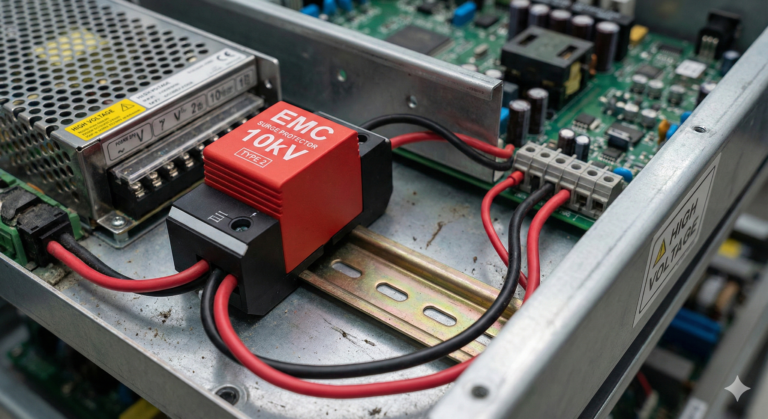

Industrial LED Lighting refers to high-intensity discharge fixtures (typically High Bays, Floods, or Street Lights) designed to maintain at least 70% of their initial brightness (L70) for over 50,000 hours. Unlike residential bulbs, true industrial fixtures require massive thermal management systems (heat sinks) to dissipate heat in non-climate-controlled environments, ensuring the Junction Temperature (Tj) remains stable.

1. The Heat Problem: Why Physics Hates Cheap Lights

Heat is the silent killer of electronics. In Lebanon, our voltage fluctuates (thanks, generator transfers), and our summers are hot.

When an LED chip operates, it generates light and heat. If that heat cannot escape, the internal temperature of the chip rises. Once the Junction Temperature exceeds its limit (usually around 85°C-105°C), the chemical structure of the phosphor degrades.

- Result A: The light loses brightness rapidly (Lumen Depreciation).

- Result B: The driver (the power supply) overheats and capacitors pop.

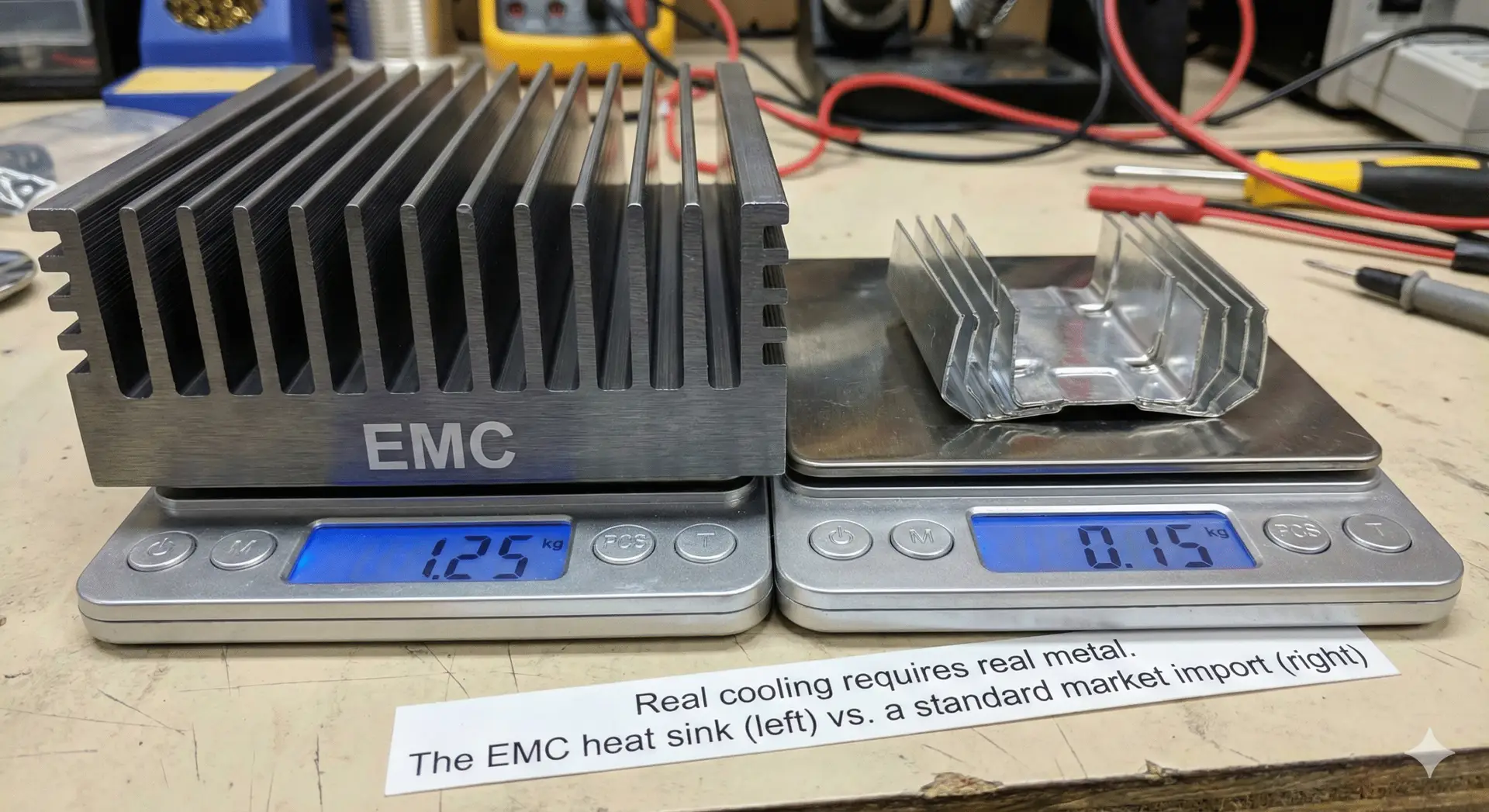

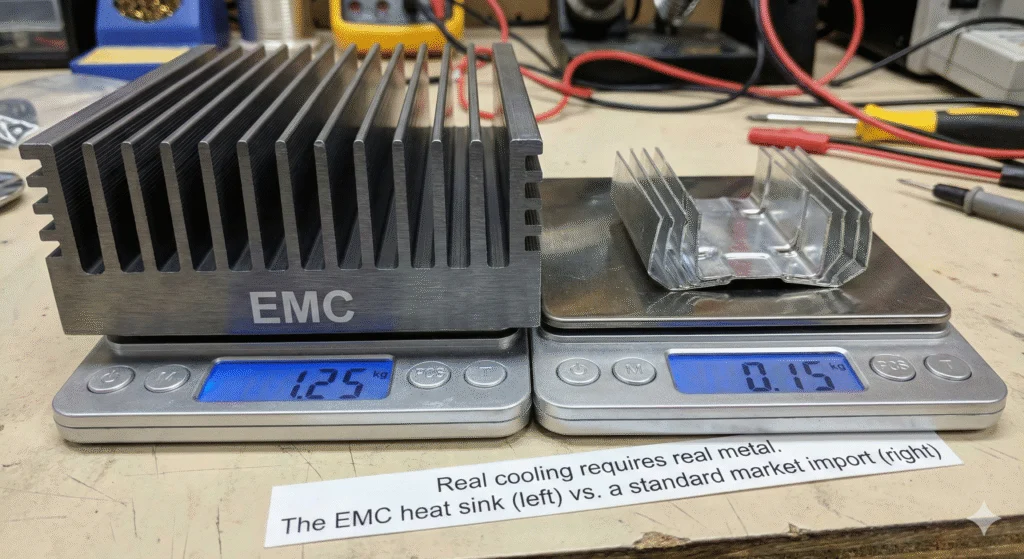

The Weight Test

The easiest way to spot a bad light? Weigh it.

Aluminum is expensive. Plastic is cheap. To save money, many generic importers use thin, stamped metal or plastic housings that look industrial but act like insulators. They trap the heat inside.

At EMC, our heat sinks are heavy. We use dense, die-cast aluminum designed to pull heat away from the chip and dump it into the air.

2. Reading the Datasheet: How to Spot a Lie

When you are comparing quotes for a big project, don’t just look at the price. Look at the data. Here are the three numbers generic suppliers usually fudge.

A. Lumens vs. System Lumens

A datasheet might claim “150 Lumens per Watt.” But is that the Source Lumen (the raw chip) or the System Lumen (the actual light coming out of the fixture)?

- Source Lumens: Calculated in a cold lab.

- System Lumens: The reality. After you put a lens over the chip (which blocks 5-10% of light) and run it hot (which loses another 5-10%), you are getting much less light than you paid for.

The EMC Promise: We quote System Lumens. We measure what actually hits your floor.

B. Power Factor (PF)

If you run a large facility, you know about “Reactive Power” fines from EDL. Cheap LED drivers have a Power Factor of 0.5 or 0.6. This means they are “dirty” loads. They draw more current than they use, heating up your cables and costing you money in efficiency losses.

- Standard Import: PF > 0.5

- EMC Industrial Spec: PF > 0.95

C. CRI (Color Rendering Index)

Who cares about color in a warehouse? You should. Low CRI lights (CRI < 70) wash out colors. Red looks brown. Yellow looks grey. In a factory where workers need to read safety labels or color-code wires, poor lighting is a safety hazard. We standardize on CRI > 80 for industrial spaces because safety isn’t optional.

3. The “Made in Lebanon” Advantage: It’s Not Patriotism, It’s Logistics

Let’s say you buy 500 High Bays from a supplier who imports from China. Two years later, 10 of them fail. You call the supplier.

- Supplier: “Sorry, that model is discontinued.”

- Supplier: “We can order a replacement, it will be here in 3 months.”

Now you have a dark spot in your factory for 3 months.

Because EMC manufactures right here in Lebanon:

- Spare Parts are Local: We stock drivers, chips, and housings.

- Instant Warranty: If a light fails (it’s rare, but physics happens), we fix it or replace it in 24-48 hours.

- Customization: Need a weird beam angle? Need a specific mounting bracket? We can build it.

4. Case Study: Saving Energy at Mercedes-Benz Lebanon

We recently worked with T. Gargour & Fils s.a.l. who was struggling with high generator bills and dark lecture halls.

The Challenge: They were using old metal halide lamps. They were hot, buzzed loudly, and ate electricity like crazy.

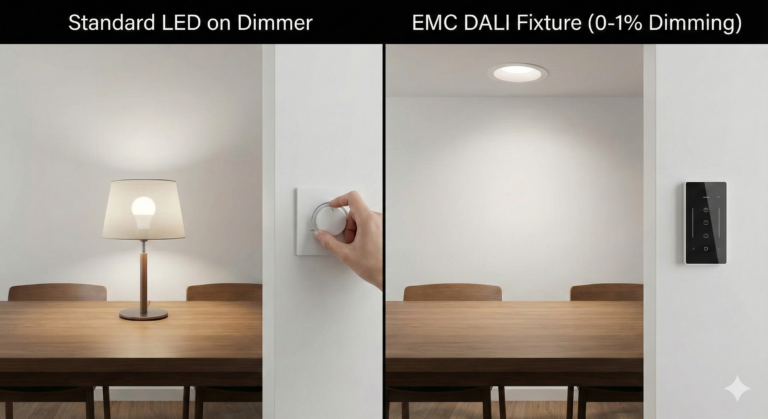

The Solution: We didn’t just swap bulbs. We ran a Dialux simulation to calculate exactly how many lumens were needed at desk height. We installed our 4*50w (200w) High Bays with a 4000K color temperature to reduce eye strain. This High Bay is somehow special because you can control each 50w Chip alone by itself. So, you can light 50w, 100w, 150w, 200w in one single lamp.

The Result:

- Energy Savings: 40% reduction in lighting load.

- Maintenance: Zero bulb changes in 2 years.

- Happy Students: No more buzzing noises during exams.

Conclusion: Stop Buying Mystery Boxes

As an engineer, I respect data. I respect quality materials. And I respect the harsh reality of the Lebanese grid. Don’t gamble your project’s reputation on a “mystery box” LED just to save a few dollars upfront. The cost of replacing that light six months later will wipe out any savings you made.

Need a technical audit? Invite us to your site. We’ll bring the lux meter, we’ll bring the samples, and we’ll show you the difference between a light bulb and an energy management solution.

Contact EMC SUPERLED, LED Lighting Experts in Mtaileb Lebanon